What is Acetate Fabric?

Acetate is a type of fabric that is made from cellulose, which is derived from wood pulp. It is a man-made cellulosic fiber, which is created by chemically treating wood pulp. It is commonly used to make clothing, linings, and home furnishings such as curtains and upholstery. Acetate fabric is known for its softness, drapability, and resistance to shrinkage, fading, and wrinkles.

It is also known for its moisture absorbency and breathability, which makes it comfortable to wear. The fabric can be dyed easily and can be blended with other fibers to create different textures and weights. The manufacturing process of acetate is relatively simple and inexpensive, which makes it an affordable option for many clothing manufacturers.

The production of acetate can have negative environmental impacts, such as the use of chemicals and the consumption of energy and water.

How is Acetate Fabric Made?

Acetate is a synthetic fabric made from cellulose, which is derived from wood pulp. The process of making acetate typically involves several steps:

Wood pulping: The first step in making acetate is to obtain cellulose from wood pulp. This can be done by using chemical processes such as the Kraft process or the sulfite process. Both of these processes involve the use of chemicals such as sodium hydroxide and sulfur dioxide, which can be harmful to the environment and human health if not properly handled and disposed of.

Acetylation: Once the cellulose has been obtained, it is then chemically treated to create cellulose acetate. This process is called acetylation and it involves the use of chemicals such as acetic anhydride and sulfuric acid. These chemicals can be toxic and harmful to human health and the environment if not properly handled and disposed of.

Spinning: The cellulose acetate is then melted and extruded through small holes, called spinnerets, to form thin fibers. These fibers are cooled and stretched to align the cellulose acetate molecules, which makes the fibers stronger and more stable.

Weaving or knitting: The fibers are then woven or knit into the acetate fabric.

Finishing: The acetate fabric is then subjected to various finishing processes, such as dyeing, cutting, and sewing, to create the desired product.

Benefits of Acetate:

“Acetate fabric is soft, lightweight, and drapes well”

Versatile: Acetate fabric is soft, lightweight, and drapes well, making it a popular choice for clothing and home furnishings.

Comfortable to wear: Acetate fabrics are breathable and moisture-absorbent, which makes them comfortable to wear.

Durable: Acetate fabrics are known for their durability and resistance to shrinking, fading, and wrinkles.

Environmentally friendly: Acetate can be produced from wood pulp, which is a renewable resource, and does not require the use of synthetic materials or chemicals.

Harmful Chemicals?

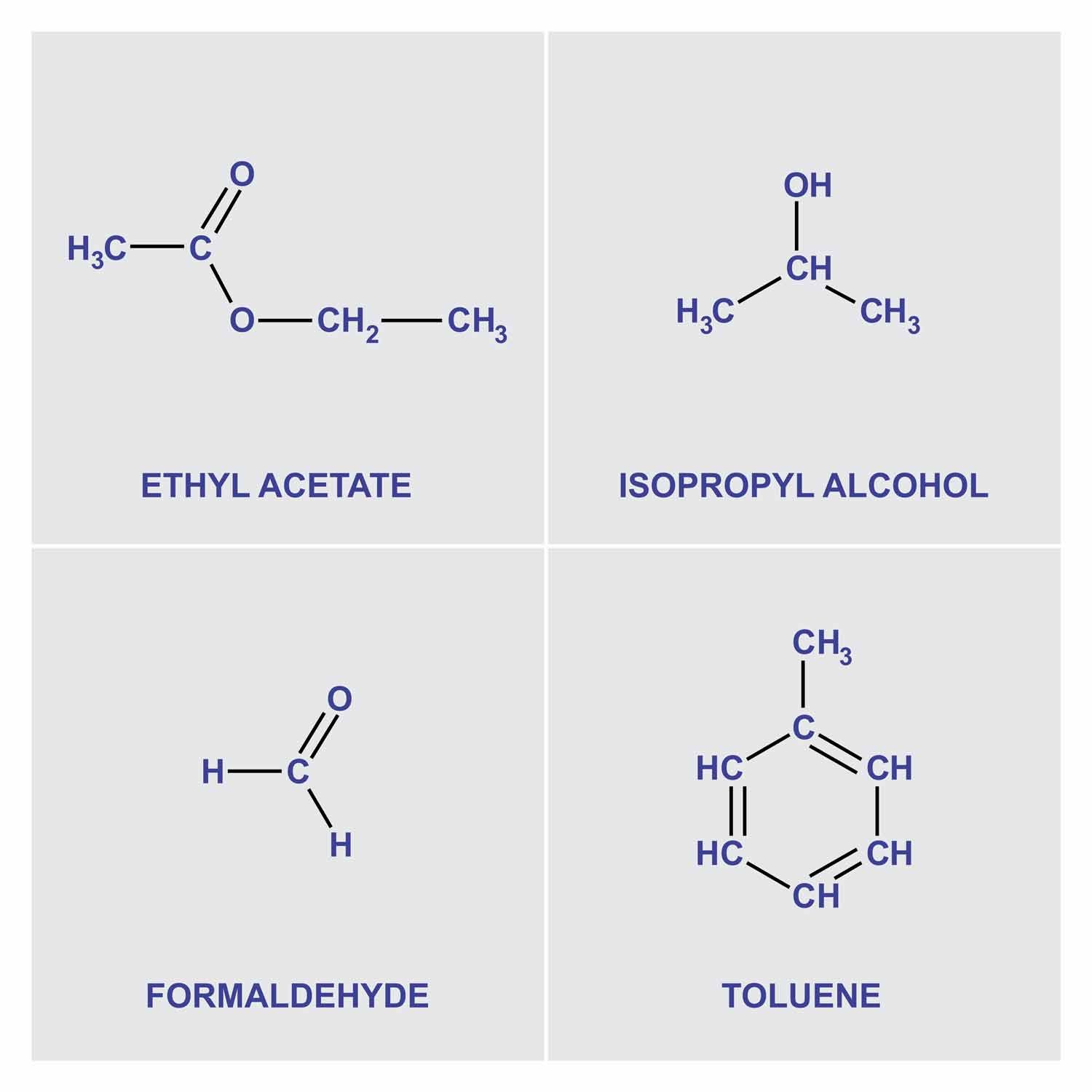

The production of acetate fabric involves the use of several harmful chemicals, including:

Acetic Anhydride: A strong irritant that can cause skin and eye irritation, respiratory problems, and chemical burns.

Sulfuric Acid: A highly corrosive chemical that can cause severe skin and eye damage, respiratory problems, and chemical burns.

Formic Acid: A corrosive chemical that can cause skin irritation, eye damage, respiratory problems, and chemical burns.

Methanol: A toxic chemical that can cause headaches, dizziness, nausea, and blindness if ingested or inhaled in large quantities.

Toluene: A toxic chemical that can cause respiratory problems, dizziness, headaches, and damage to the central nervous system if inhaled in large quantities.

Types of Products using Acetate Fabric?

Acetate fabric is used in the production of a variety of products, including:

Clothing: Acetate is commonly used in the production of women's dresses, blouses, and lingerie due to its soft, silky feel and draping properties.

Home Textiles: Acetate is used in the production of bed sheets, curtains, tablecloths, and other home textiles due to its easy care and wrinkle-resistant properties.

Decorative Fabrics: Acetate is often used in the production of decorative fabrics such as lampshades and trimming due to its smooth and lustrous appearance.

Trimmings and Ribbons: Acetate is commonly used in the production of ribbon and trimming due to its soft and pliable nature.

Film: Acetate is used as a base material for photographic film due to its transparency and ability to be easily processed.

Medical and Industrial Textiles: Acetate is used in the production of medical textiles such as surgical gowns and drapes, and in industrial textiles for filtration and separation applications.

Important Certifications

There are several important certifications and standards related to acetate fabric, including:

“certification that verifies the use of recycled materials in the production of acetate fabric and assesses the environmental and social impacts of the production”

OEKO-TEX Standard 100: A globally recognized certification that verifies the safety of textiles and accessories for human health. This certification tests for harmful substances, such as heavy metals, formaldehyde, and prohibited azo dyes, in acetate fabric.

Global Recycled Standard (GRS): A certification that verifies the use of recycled materials in the production of acetate fabric and assesses the environmental and social impacts of the production process.

Global Organic Textile Standard (GOTS): A certification that verifies the use of organic fibers, such as organic cotton, in the production of acetate fabric and assesses the environmental and social impacts of the production process.

Bluesign System: A certification that evaluates the environmental, social, and health impacts of the production of textiles, including acetate fabric, and ensures the use of sustainable and responsible production practices.

Having these certifications can demonstrate a company's commitment to sustainability and environmental responsibility and can help consumers make informed decisions about the products they purchase.

Alternative Fabrics to Acetate

Tencel: Tencel is a sustainable and eco-friendly fabric made from wood pulp that is sourced from responsibly managed forests. Tencel is soft, breathable, and has a silky feel that makes it a popular alternative to acetate for use in formal wear and other clothing. Tencel is produced using an environmentally friendly closed-loop process that minimizes waste and water use.

Linen: Linen is a natural fabric made from the fibers of the flax plant. It is a sustainable and eco-friendly fabric that is breathable, durable, and has a textured feel. Linen is often used in summer clothing and home textiles, and is a popular alternative to acetate for those who prefer natural fabrics.

Cupro: Cupro is a regenerated cellulose fabric made from cotton waste. It has a soft and silky feel that makes it a popular alternative to acetate for use in formal wear and other clothing. Cupro is produced using an environmentally friendly closed-loop process that minimizes waste and water use, making it a more sustainable alternative to acetate.

How is Acetate Fabric Improving

Acetate, a synthetic fabric made from cellulose, has traditionally been associated with negative environmental impacts due to the energy-intensive production process and the use of chemicals. However, in recent years, some companies have started to take steps to make the production of acetate more sustainable and environmentally friendly. Here are a few examples:

Using sustainable wood pulp: Some companies are sourcing wood pulp from responsibly managed forests or using recycled cellulose fibers to minimize the environmental impact of the production of acetate.

Using non-toxic dyes: Some companies are switching to non-toxic dyes during the production process, which can reduce the amount of harmful chemicals released into the environment.

Reducing water and energy consumption: Some companies are implementing water-saving and energy-efficient technologies during the production process to reduce their environmental footprint.

Certifications: Some companies are obtaining certifications such as Global Recycled Standard (GRS) or the Bluesign system, which are third-party certifications that ensure that the product meets certain environmental and social standards.

Biodegradability: Some companies are working on making acetate biodegradable or compostable.

FAQ

Is acetate fabric environmentally friendly?

Acetate fabric is not considered to be environmentally friendly, as it is made from non-renewable resources and the production process can be resource-intensive. Additionally, the fabric may shed microplastics during washing, which can contribute to ocean pollution.

How does acetate fabric compare to other synthetic fabrics?

Acetate fabric is similar to other synthetic fabrics, such as polyester and nylon, in that it is lightweight, durable, and easy to care for. However, acetate fabric has a softer feel and a more lustrous sheen than these other fabrics, which makes it popular for use in formal attire.

How should I care for acetate fabric?

Acetate fabric can be cared for in a similar way to silk, as it is sensitive to heat and can be damaged by high temperatures. Acetate fabric should be hand-washed or washed on a delicate cycle with cool water, and should be air-dried or dried on a low heat setting. It is important to avoid ironing or steaming acetate fabric, as this can cause the fabric to melt or become shiny.

Where can I find acetate fabric clothing and home textiles?

Acetate fabric clothing and home textiles can be found at a variety of retailers, both online and in brick-and-mortar stores. However, due to its environmental impact, it is not a fabric that is commonly used in sustainable or eco-friendly fashion. If you are looking for more sustainable fabric options, consider choosing fabrics made from organic or recycled materials.

Final Thoughts

Acetate fabric is a synthetic material made from cellulose acetate and is known for its soft and silky feel, draping properties, and easy care. It is widely used in the production of clothing, home textiles, and decorative fabrics.

The production of acetate fabric involves the use of harmful chemicals, such as acetic anhydride, sulfuric acid, and formic acid, which can have adverse effects on workers and the environment if not properly handled. The disposal of acetate fabric and its by-products can also have negative environmental impacts, as cellulose acetate is not biodegradable and can take hundreds of years to break down in the environment.

Despite its negative environmental impact, acetate fabric remains popular due to its attractive appearance, durability, and ease of care.